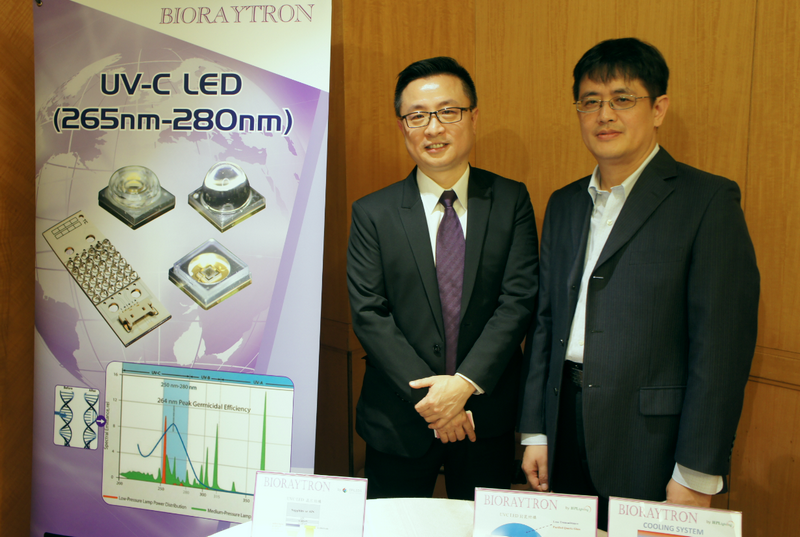

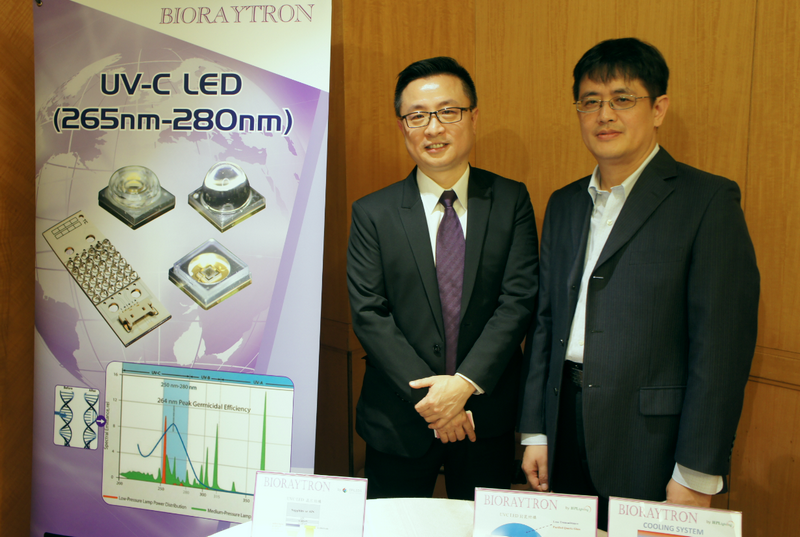

The UVC deep ultraviolet disinfection market is widely used, with a global output value of US$25 billion. Taiwan's LED factory Guangsheng and Yanjing are optimistic about the potential applications and business opportunities of UVC LEDs. The joint venture creates the brand "Bioraytron" to integrate the upstream and downstream technology advantages of the industry, and launches UVC LED packaging products from 265 nm to 275 nm, and plans to introduce people's livelihood consumption. , medical sterilization and testing equipment, industrial and high-tech water sterilization treatment and other industrial fields.

In recent years, the LED industry has encountered price pressures and many bottlenecks, so it is urgent to find a new way out. Dr. Wei Zhihong, Chairman and General Manager of Yanjing Optoelectronics, said that the purpose of working with Optoelectronics is to integrate technology and establish technical thresholds to create a new operating model and jointly create new industries rather than just making new products. Bioraytron products are divided into optical and crystallographic technologies. Optical Fiber is responsible for the production of UVC LED epitaxial wafers and wafers. It is exclusively supplied to Yanjing for packaging of UVC LED components and module products. It is sold to deep UV UVC industry customers through the Bioraytron brand. .

The UVC band is from 200 nm to 280 nm. The main function is disinfection and detection materials, which can be widely used in air/water/surface purification, medical testing equipment, food preservation and other markets. Dr. Wei Zhihong pointed out that there are two main points of disinfection and sterilization. First, the correct wavelength should be selected, and the absorption spectrum of bacteria and microorganisms should be about 264 nm. Second, the dose (Dose) should be sufficient to effectively play the role of sterilization. "Dose (mJ/cm 2 ) = UVC radiation intensity (mW/cm 2 ) x time (Sec)", the higher the UVC radiation intensity, the shorter the sterilization time, so to achieve the "second kill" degree, UVC LED The light intensity must be increased.

Xu Mingsen, general manager of Optoelectronics Technology, said that time is the key to entering the consumer application market. Once the wavelength is chosen, the sterilization time can be shortened, and the UV LED performance is improved, including increasing the light intensity, reducing the angle, etc. better. Bioraytron's UVC LED products are capable of achieving the world's highest radiation intensity of 25mW/cm 2 at a radiation distance of 10 mm and an input power of 1.2 W for a UV- LED LED US-Japan plant. Effectively shortens sterilization time and increases product design freedom.

At present, Bioraytron's UVC LED package products have reached the light output of 1 to 4 US dollars per milliwatt (mW), and will continue to work at a higher cost. Bioraytron will give priority to the Minsheng consumer industry in 2017, and the annual production capacity of UVC LED will reach 5 million. Next, it will be introduced into the medical sterilization and testing equipment, industrial water sterilization and other industries. 50 million, in addition to the simultaneous development of UVB LED applications.

The UVC deep ultraviolet disinfection market is widely used, with a global output value of US$25 billion. Taiwan's LED factory Guangsheng and Yanjing are optimistic about the potential applications and business opportunities of UVC LEDs. The joint venture creates the brand "Bioraytron" to integrate the upstream and downstream technology advantages of the industry, and launches UVC LED packaging products from 265 nm to 275 nm, and plans to introduce people's livelihood consumption. , medical sterilization and testing equipment, industrial and high-tech water sterilization treatment and other industrial fields.

In recent years, the LED industry has encountered price pressures and many bottlenecks, so it is urgent to find a new way out. Dr. Wei Zhihong, Chairman and General Manager of Yanjing Optoelectronics, said that the purpose of working with Optoelectronics is to integrate technology and establish technical thresholds to create a new operating model and jointly create new industries rather than just making new products. Bioraytron products are divided into optical and crystallographic technologies. Optical Fiber is responsible for the production of UVC LED epitaxial wafers and wafers. It is exclusively supplied to Yanjing for packaging of UVC LED components and module products. It is sold to deep UV UVC industry customers through the Bioraytron brand. .

The UVC band is from 200 nm to 280 nm. The main function is disinfection and detection materials, which can be widely used in air/water/surface purification, medical testing equipment, food preservation and other markets. Dr. Wei Zhihong pointed out that there are two main points of disinfection and sterilization. First, the correct wavelength should be selected, and the absorption spectrum of bacteria and microorganisms should be about 264 nm. Second, the dose (Dose) should be sufficient to effectively play the role of sterilization. "Dose (mJ/cm 2 ) = UVC radiation intensity (mW/cm 2 ) x time (Sec)", the higher the UVC radiation intensity, the shorter the sterilization time, so to achieve the "second kill" degree, UVC LED The light intensity must be increased.

Xu Mingsen, general manager of Optoelectronics Technology, said that time is the key to entering the consumer application market. Once the wavelength is chosen, the sterilization time can be shortened, and the UV LED performance is improved, including increasing the light intensity, reducing the angle, etc. better. Bioraytron's UVC LED products are capable of achieving the world's highest radiation intensity of 25mW/cm 2 at a radiation distance of 10 mm and an input power of 1.2 W for a UV- LED LED US-Japan plant. Effectively shortens sterilization time and increases product design freedom.

At present, Bioraytron's UVC LED package products have reached the light output of 1 to 4 US dollars per milliwatt (mW), and will continue to work at a higher cost. Bioraytron will give priority to the Minsheng consumer industry in 2017, and the annual production capacity of UVC LED will reach 5 million. Next, it will be introduced into the medical sterilization and testing equipment, industrial water sterilization and other industries. 50 million, in addition to the simultaneous development of UVB LED applications. 2018-10-14 23:38:19

Guangxu and Yanjing create a branded UVC LED market, which will

The UVC deep ultraviolet disinfection market is widely used, with a global output value of US$25 billion. Taiwan's LED factory Guangsheng and Yanjing are optimistic about the potential applications and business opportunities of UVC LEDs. The joint venture creates the brand "Bioraytron" to integrate the upstream and downstream technology advantages of the industry, and launches UVC LED packaging products from 265 nm to 275 nm, and plans to introduce people's livelihood consumption. , medical sterilization and testing equipment, industrial and high-tech water sterilization treatment and other industrial fields.

In recent years, the LED industry has encountered price pressures and many bottlenecks, so it is urgent to find a new way out. Dr. Wei Zhihong, Chairman and General Manager of Yanjing Optoelectronics, said that the purpose of working with Optoelectronics is to integrate technology and establish technical thresholds to create a new operating model and jointly create new industries rather than just making new products. Bioraytron products are divided into optical and crystallographic technologies. Optical Fiber is responsible for the production of UVC LED epitaxial wafers and wafers. It is exclusively supplied to Yanjing for packaging of UVC LED components and module products. It is sold to deep UV UVC industry customers through the Bioraytron brand. .

The UVC band is from 200 nm to 280 nm. The main function is disinfection and detection materials, which can be widely used in air/water/surface purification, medical testing equipment, food preservation and other markets. Dr. Wei Zhihong pointed out that there are two main points of disinfection and sterilization. First, the correct wavelength should be selected, and the absorption spectrum of bacteria and microorganisms should be about 264 nm. Second, the dose (Dose) should be sufficient to effectively play the role of sterilization. "Dose (mJ/cm 2 ) = UVC radiation intensity (mW/cm 2 ) x time (Sec)", the higher the UVC radiation intensity, the shorter the sterilization time, so to achieve the "second kill" degree, UVC LED The light intensity must be increased.

Xu Mingsen, general manager of Optoelectronics Technology, said that time is the key to entering the consumer application market. Once the wavelength is chosen, the sterilization time can be shortened, and the UV LED performance is improved, including increasing the light intensity, reducing the angle, etc. better. Bioraytron's UVC LED products are capable of achieving the world's highest radiation intensity of 25mW/cm 2 at a radiation distance of 10 mm and an input power of 1.2 W for a UV- LED LED US-Japan plant. Effectively shortens sterilization time and increases product design freedom.

At present, Bioraytron's UVC LED package products have reached the light output of 1 to 4 US dollars per milliwatt (mW), and will continue to work at a higher cost. Bioraytron will give priority to the Minsheng consumer industry in 2017, and the annual production capacity of UVC LED will reach 5 million. Next, it will be introduced into the medical sterilization and testing equipment, industrial water sterilization and other industries. 50 million, in addition to the simultaneous development of UVB LED applications.

The UVC deep ultraviolet disinfection market is widely used, with a global output value of US$25 billion. Taiwan's LED factory Guangsheng and Yanjing are optimistic about the potential applications and business opportunities of UVC LEDs. The joint venture creates the brand "Bioraytron" to integrate the upstream and downstream technology advantages of the industry, and launches UVC LED packaging products from 265 nm to 275 nm, and plans to introduce people's livelihood consumption. , medical sterilization and testing equipment, industrial and high-tech water sterilization treatment and other industrial fields.

In recent years, the LED industry has encountered price pressures and many bottlenecks, so it is urgent to find a new way out. Dr. Wei Zhihong, Chairman and General Manager of Yanjing Optoelectronics, said that the purpose of working with Optoelectronics is to integrate technology and establish technical thresholds to create a new operating model and jointly create new industries rather than just making new products. Bioraytron products are divided into optical and crystallographic technologies. Optical Fiber is responsible for the production of UVC LED epitaxial wafers and wafers. It is exclusively supplied to Yanjing for packaging of UVC LED components and module products. It is sold to deep UV UVC industry customers through the Bioraytron brand. .

The UVC band is from 200 nm to 280 nm. The main function is disinfection and detection materials, which can be widely used in air/water/surface purification, medical testing equipment, food preservation and other markets. Dr. Wei Zhihong pointed out that there are two main points of disinfection and sterilization. First, the correct wavelength should be selected, and the absorption spectrum of bacteria and microorganisms should be about 264 nm. Second, the dose (Dose) should be sufficient to effectively play the role of sterilization. "Dose (mJ/cm 2 ) = UVC radiation intensity (mW/cm 2 ) x time (Sec)", the higher the UVC radiation intensity, the shorter the sterilization time, so to achieve the "second kill" degree, UVC LED The light intensity must be increased.

Xu Mingsen, general manager of Optoelectronics Technology, said that time is the key to entering the consumer application market. Once the wavelength is chosen, the sterilization time can be shortened, and the UV LED performance is improved, including increasing the light intensity, reducing the angle, etc. better. Bioraytron's UVC LED products are capable of achieving the world's highest radiation intensity of 25mW/cm 2 at a radiation distance of 10 mm and an input power of 1.2 W for a UV- LED LED US-Japan plant. Effectively shortens sterilization time and increases product design freedom.

At present, Bioraytron's UVC LED package products have reached the light output of 1 to 4 US dollars per milliwatt (mW), and will continue to work at a higher cost. Bioraytron will give priority to the Minsheng consumer industry in 2017, and the annual production capacity of UVC LED will reach 5 million. Next, it will be introduced into the medical sterilization and testing equipment, industrial water sterilization and other industries. 50 million, in addition to the simultaneous development of UVB LED applications.